For construction companies, door, window, and curtain wall enterprises, etc., choosing an aluminum profile supplier is not simply about comparing prices and placing orders, but about finding a reliable partner with whom they can collaborate for the long term. Choosing the right aluminum profile supplier not only avoids problems such as rework and claims later in the project but also ensures the quality of project delivery and the stability of long-term cooperation. The suppliers in the market are of mixed quality. Just looking at the price or the samples is far from enough. Based on years of industry experience, Shenghai Aluminum list 5 opinion to help you find reliable supplier.

Capacity and Delivery

Production capacity: Prioritize selecting self-owned factories with complete production lines, including extrusion, oxidation, spraying, and deep processing, to ensure suppliers can handle large orders. It is also necessary to check whether advanced equipment is equipped. When dealing with irregular and unconventional profiles, the precision of the equipment is a great test.

Delivery: The key lies in whether the promised delivery period can be truly fulfilled. At the same time, understand the emergency response capability: can urgent orders be replenished quickly, and can the production plan be coordinated?

In addition, is there a dedicated, experienced person in charge throughout the process to proactively synchronize production progress with on-site photos at key points, such as extrusion, surface treatment, and deep processing? Whether the other party responds promptly to changes in project requirements.

Service and After-sales

A truly professional supplier provides services throughout the project. Could you, based on the specific project application, propose suitable aluminum alloy substrates, such as the conventional 6063-T5 and 6061-T6, from a professional perspective and in accordance with structural requirements? Based on the drawings, identify in advance potential design hazards that may lead to difficult extrusion, insufficient strength, or installation risks, and propose optimization plans.

In addition, is there a dedicated, experienced person in charge throughout the process to proactively synchronize production progress with on-site photos at key points, such as extrusion, surface treatment, and deep processing? Whether the other party responds promptly to changes in project requirements.

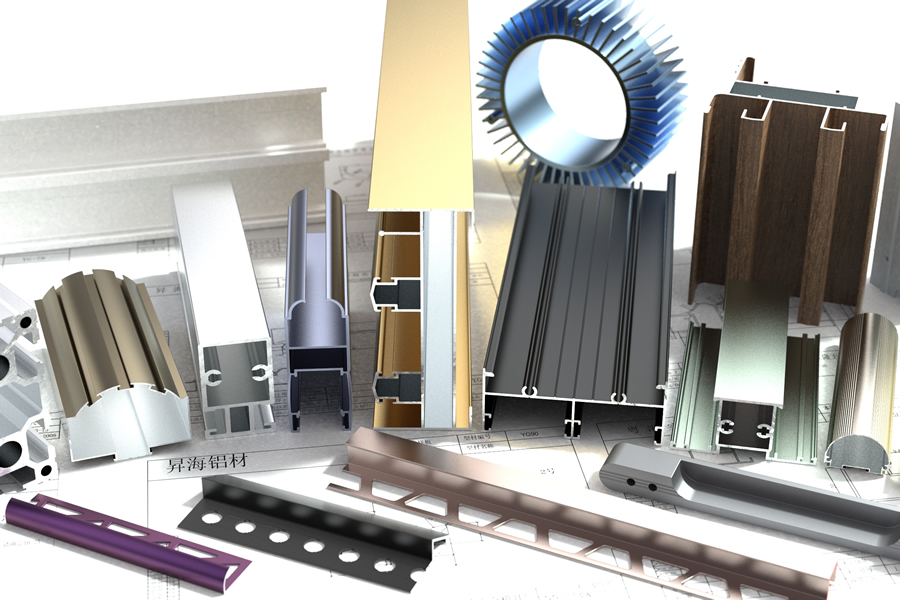

Customization Capability

When working on projects, it is inevitable to encounter non-standard requirements. When the drawings are provided to the supplier, can they quickly understand them and offer reasonable optimization suggestions? For instance, for non-standard sections, could suggestions such as adjusting the wall thickness of the profile and optimizing the structure be proposed based on extrusion feasibility, rather than producing to order?

Surface treatment and color: If the project requires special colors, can the supplier precisely match the colors and ensure that the color and texture of each batch are consistent? Whether the achieved effect is uniform and firm, and whether the weather resistance meets the standards.

Quality Control

The key point to check is whether it has quality certification. This is the basic threshold. Then check the material certification and surface treatment test reports to confirm that the product complies with industry standards. Understand the full process control from the source of aluminum ingots, extrusion process parameters, the performance of surface treatment to finished product inspection, and prove the batch consistency of its products.

Actual Cases

Actual cases have better persuasiveness. It’s not about the quantity, but about what troubles have been solved and how they were solved.

If you are purchasing aluminum profiles, check whether the supplier has completed similar projects. You can ask the other party to present several relevant successful cases and inquire: What was the biggest challenge encountered in a certain project? How to solve it? A supplier with real experience in solving difficult problems truly understands your needs.

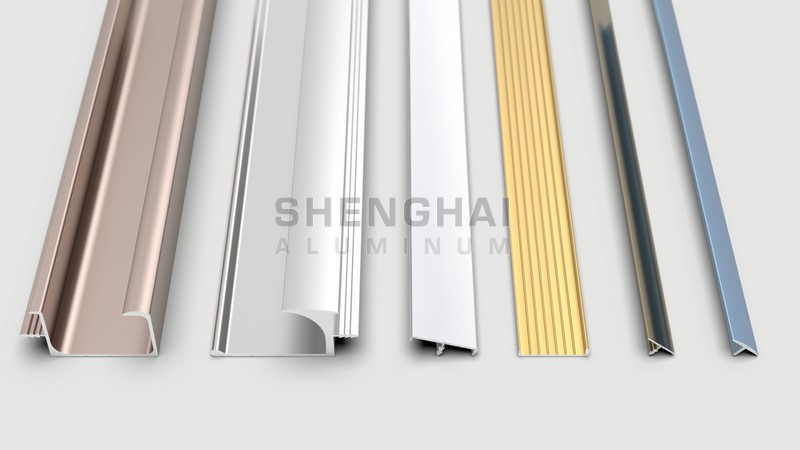

Selecting a supplier is essentially about finding a long-term and reliable solution partner for the project. If you are looking for a professional Aluminum profile supplier, you might as well learn about Shenghai Aluminum. Whether it’s standardized aluminum profiles such as curtain walls, handles, and window and door thermal break profiles, or customized aluminum profile demands, we can provide an integrated solution from R&D, mold design to production and delivery. We firmly believe that transparent communication and reliable execution are the foundation of long-term cooperation.